The Molten Salt Hybrid

A "Leisurely Walk" to a Fusion Economy

by C.P. Hager, Jr. (c) 1981, 1998

[This article appeared in the July 1981 issue of Fusion magazine]

CONTROLLED THERMONUCLEAR FUSION will soon pass the milestone of breakeven--the demonstration of scientific feasibility. Breakeven, however, is but the first step along the road that ultimately leads to the realization of commercial fusion power. Past experience with the introduction of new technologies suggests that the road could prove to be a long one. Controlled fission, for example, was initially demonstrated in 1942, and the Shippingport, Pennsylvania nuclear plant was operating in 1957, yet nearly three decades elapsed before the technology achieved fairly widespread commercialization.

Fusion technology, if it conforms to this pattern, offers the industrialized world no surcease from its immediate energy problems. Fortunately, however, a way station on the road to fusion power exists in the form of the fusion-fission hybrid. With this system, the time needed to bring fusion power on line could be cut in half.

The crucial question is why can't a crash program bring fusion on line in 10 to 15 years? The answer lies in the fact that technological innovation moves through two distinct phases: a development phase and a deployment phase. The deployment phase is primarily a matter of logistics and economics and is influenced by such factors as the ease of capital formation, the availability of trained manpower, and even the efficiency with which the sub-sub-contractor in Kankakee turns out widgets. Orchestrating a large enterprise such as the introduction of fusion power is very difficult, and bottlenecks are sure to develop. In contrast, the hybrid could readily plug into existing nuclear power technology because the hybrid is first and foremost a source of fissile material. This, combined with the fact that a small number of hybrids can fuel a large number of fission reactors, results in a much more easily managed deployment.

Another point in favor of the hybrid is that it is already very nearly state-of-the-art. This is because it is in essence a plasma amplifier, using the rich flux of 14.1-MeV (Million electron Volts) neutrons from the deuterium-tritium (DT) reaction to induce large numbers of fissions, each of which releases approximately 200 MeV. Usable power from a hybrid could be obtained with a very modest plasma performance, thus relaxing many of the stringent engineering requirements intrinsic to pure fusion systems.

To date, a multitude of different hybrid designs have been suggested. Some would use solid blankets of depleted uranium in which plutonium would be bred. Others would utilize solid blankets of thorium in order to breed uranium-233 (U-233), which is optimally efficient in thermal reactors. One design, intended to be compatible with the West German pebble-bed high temperature gas-cooled reactor (HTGR), would use unenriched fuel spheres as the breeding blanket, the idea being to enrich them in the hybrid and then transfer them directly, without reprocessing, to a waiting HTGR.

Perhaps the most promising design to emerge in recent years is of a hybrid with a fluid blanket composed of a molten fluoride salt. What is unique about this design is that the blanket material would be continuously reprocessed in situ by a small chemical plant integral to the reactor.

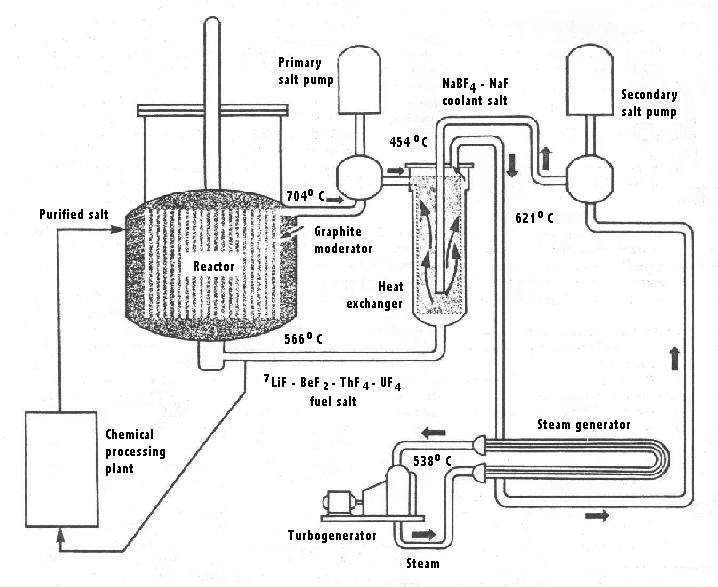

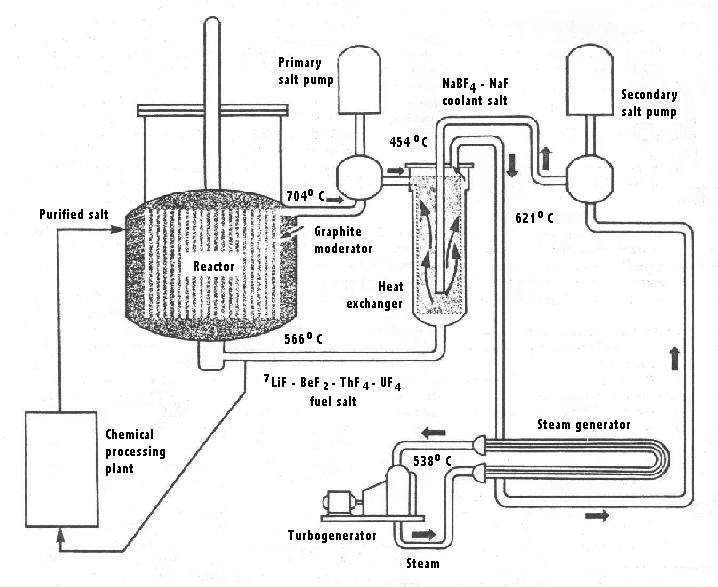

In situ reprocessing and a fluid blanket are spinoffs from the molten salt reactor program, which sought to develop a fluid-fuel thermal breeder reactor, the Molten Salt Breeder Reactor (MSBR). Oak Ridge National Laboratory's conceptual design for a 1,000-Mwe (Megawatt electric) MSBR

1 is shown in Figure 1 and described in Table 1.

|

Figure 1. The Molten Salt Breeder Reactor

Unlike conventional readers having solid core assemblies, the Molten Salt Reactor (MSR) is fueled by a circulating mixture of a liquid carrier salt and uranium fluoride. The initial motivation for the development of the MSR was to produce a small, high-performance power plant for an intercontinental nuclear-powered bomber. After the demonstration of such a power plant in 1954, the project was abandoned, and the focus shifted toward the MSR as a commercial electrical power plant.

The MSR has a number of potential advantages over solid-fueled reactors. The most important is that the fuel salt (which also acts as the heat-transfer medium) can be circulated through a processing unit where waste products can be removed. In solid fuel reactors, fission products accumulate in the fuel assemblies. Many of these products have high neutron absorption cross sections. Removal of these radioactive species allows a reactor to operate with a lower fissile loading, which has both economic and safely ramifications. The fuel utilization of the MSR can be further enhanced by sequestering the protactinium-233 produced from thorium-232 in the fuel salt, allowing it to decay into fissile uranium-233. This additional processing step allows the MSR to become a full-fledged breeder reactor.

Two problems, thought to be major impediments to the commercial development of the MSR, were essentially solved before the developmental program was terminated in 1976. The problem of corrosion of the structural material by the fuel and certain entrained fission by-product compounds (particularly tellurium compounds) was corrected by modifying the composition of the Hastelloy-N structural material. The second problem, the control of tritium produced by the neutron bombardment of the lithium constituent in the salt, was solved when it was discovered that the coolant salt, sodium fluoroborate, trapped nearly 98 percent of the tritium diffusing across the heat exchanger boundary. This discovery is particularly important for molten salt blankets in fusion hybrid reactor systems. |

|

Table 1

Operating Parameters of a 1,000-Mwe

Molten Salt Breeder Reactor

Thermal power 2,250 MW

Electric power 1,000 MW

Plant lifetime 30 years

Fuel processing On-line continuous

Fissile inventory 1,500 kg

Breeding ratio 1.065

Plant doubling time 20 years

Thermal efficiency 44%

Fuel salt composition 7LiF - BeF2 - ThF4 - UF4

(primary circuit) (71.7 - 16.0 - 12.0 - 0.3 mole%)

Moderator Unclad, sealed graphite

Reactor vessel material Modified Hastelloy-N

Power density 22 kW/liter

Vessel design pressure 517 kPa (75 psia)

Peak thermal neutron flux 8.3 x 1014 neutrons/cm2-sec

Coolant salt composition Eutectic sodium flouroborate

(secondary circuit) NaBF4 - NaF (92 - 8.0 mole%) |

A test-bed nonbreeding molten salt reactor, called the Molten Salt Reactor Experiment, was constructed and operated from 1965 to 1969, providing valuable information relating to systems engineering, reactor kinetics, and overall reliability. Although dropped by the government in order to focus effort on the Liquid Metal Fast Breeder Reactor (LMFBR), the program did record some important achievements before its termination:

- the demonstration of the feasibility of the reprocessing system on a laboratory scale;

- the development of a method of controlling the tritium produced by the neutron bombardment of the lithium component of the salt; and,

- the establishment of the validity of a modified Hastelloy-N as the primary system structural material.

Each of these achievements bears directly on the functioning of the Molten Salt Hybrid Reactor (MSHR).

The on-site reprocessing system would function in the MSHR in a manner analogous to a kidney in a human being. The system designed for the MSBR was to perform three tasks:

- continuous removal of fission product noble gases (xenon and krypton) as well as some tritium (mostly as tritium fluoride);

- continuous removal of fission-product rare earths and alkali earths; and,

- removal for subsequent decay of the uranium-233 precursor, protactinium-233.

The MSHR on-site reprocessing system would be similar, although certain modifications might be required depending upon blanket multiplication factors. On-site reprocessing would confer a number of advantages on the MSHR compared to other hybrid systems that rely on conventional reprocessing alternatives (for example, PUREX or THOREX). Projections of MSBR fuel-cycle economics in comparison with other reactor systems ranging from the Light Water Breeder Reactor and CANDU to the LMFBR and Gas-Cooled Fast Breeder Reactor show the MSBR to be superior to all but the advanced oxide LMFBR.

The reasons for the MSBR's low fuel cycle costs would apply with equal force to the MSHR. Solid blanket hybrids would have to shut down to replace their blanket elements; the MSHR would not, thereby attaining a higher capacity factor. Blanket elements for typical hybrid designs would require complex engineering; the MSHR's salt blanket would not. The lifetime high-level waste produced by MSHR operation could be stored on site to be removed at final plant shutdown. This would simplify and lower the costs of waste handling.

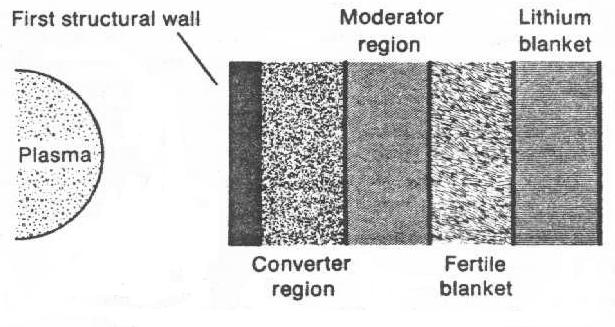

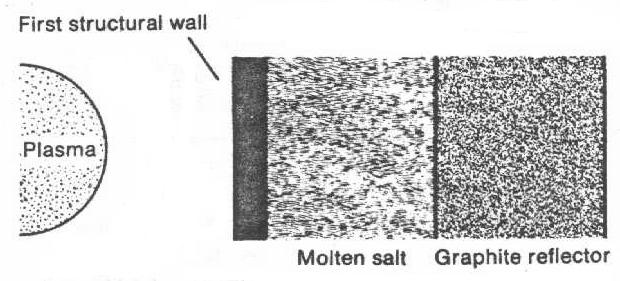

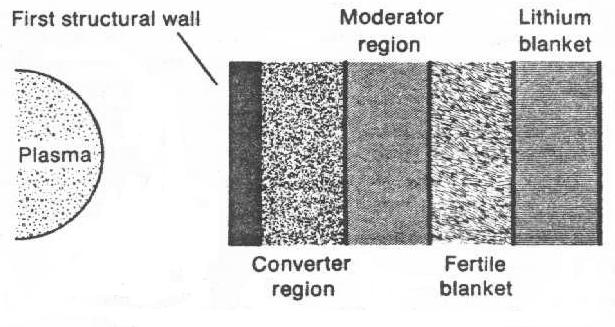

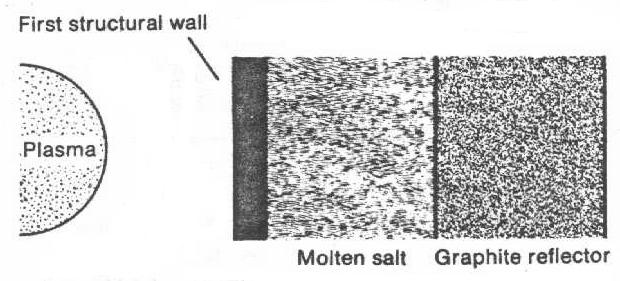

Figures 2 and 3 show the blanket designs envisioned for typical hybrids

2 and molten salt hybrids3, respectively. In the typical hybrid design, the part of the blanket located just behind the first wall is the converter region (generally made of depleted uranium). It is here that primary neutron multiplication occurs with the energetic DT neutrons causing (n,2n), (n,3n), and fast fission reactions in the uranium. All these additional neutrons can be put to work both to provide criticality in a fission blanket and breeding in a fertile blanket. Excess neutrons would be captured in an outer lithium blanket to produce the tritium needed to sustain hybrid operation. In the MSHR the salt, which is composed of 71 percent lithium fluoride, 2 percent beryllium fluoride, and 27 percent thorium fluoride (as measured in moles), would perform all of these functions.

It should also be noted that, broadly speaking, blanket design is not greatly affected by the type of fusion machine acting as the ultimate source. Hence, one could assume a mirror, tokamak, laser, fight-ion, or heavy-ion fusion machine producing the plasma in the diagrams.

|

Figure 2. Typical hybrid blanket arrangement

This schematic shows a cross section of a possible blanket configuration for a hybrid reactor. The goal of a blanket design is twofold: first, to maximize neutron production and, second, to optimize neutron utilization. The converter region (generally assumed to consist of depleted U-238), in line with the first goal, multiplies the number of neutrons available. These neutrons are then moderated and put to work to breed fissile plutonium or U-233 as well as to support fission in some of the fissile material produced in the blanket.

It should be noted that a hybrid would produce approximately 4 neutrons per 14-MeV fusion neutron versus about 2.5 neutrons produced per fission in a fast breeder. Virtually all the hybrid neutrons, however, would be available for fissile production, whereas the breeder must use one of the fission-produced neutrons to sustain criticality. With proper blanket design, commercially feasible hybrids are possible with plasma-power multiplication factors at or slightly above unity. In other words the hybrid is a near-certain possibility. |

|

Figure 3. Possible Molten Salt Hybrid blanket arrangement

The fluid blanket is suggested as an alternative to a solid blanket in order to adapt the molten salt breeder reactor reprocessing system to a hybrid, thereby allowing U-233 and Pa-233 to be removed almost as rapidly as it is produced. This would increase the net fissile production because fewer neutrons would be wasted fissioning the U-233 or converting the Pa-233 into useless U-234. Secondary considerations would include the perceived economic advantage of a continuous reprocessing system as well as possible safety benefits. |

Hybrids: Fuel and Power

All hybrids can be divided into two main types, fuel factories and power hybrids. Fuel factories emphasize fissile production at the expense of power multiplication, whereas power hybrids can generate considerable usable energy. Lawrence Livermore National Laboratory has designed a molten salt blanket system for a fuel factory driven by a mirror machine. The LLNL design maximizes fissile production in three ways.

First, blanket fissions are suppressed by rapid removal of both protactinium-233 and uranium-233. This would greatly reduce the amount of fission products present in the blanket, thereby simplifying the reprocessing system in comparison with the MSBR's system mentioned previously. This, in turn, would mean that the blanket would be relatively "clean." In fact, LLNL projects that the radioactivity in the blanket would be less than that of the activated structural materials.

Second, tritium produced by bombardment of the lithium constituent of the salt would be removed for use as fuel in fusion reactors. The chemical composition of the salt would be such that tritium production would balance fuel requirements. The application of the MSBR's proven tritium-handling technique to the hybrid's reprocessing system would greatly simplify the problem of tritium control.

Third, neutron multiplication would be assisted by using rods containing powdered beryllium located in the salt blanket. The additional neutrons would enhance U-233 production.

It is estimated that this system would be able to achieve a support ratio of 50 or more thermal reactors fueled by each hybrid reactor.

A power hybrid would be similar to a fuel factory except that substantially more fissioning would take place in the blanket. The role of the power hybrid within the energy economy would be the same as that of the LMFBR -- to feed electricity into the grid and to produce fissile material in excess of needs. Oak Ridge has designed a power-producing MSHR in a 1,000-MWe system. This MSHR would produce enough U-233 to support approximately eight standard light water reactors (LWR) operating on a once-through fuel cycle. The LMFBR, for comparison, could support less than one-half LWR per breeder. All things being equal, continuous reprocessing would tend to favor the MSHR over the LMFBR in terms of overall capacity factor.

Taking the comparison a step further, an MSHR would also offer safety benefits over the LMFBR. A number of accident scenarios that are considered quite serious with the LMFBR are either impossible or relatively minor affairs with the MSHR, for several reasons. The MSHR is significantly subcritical because it depends on the neutron flux from the plasma to sustain operation. An LMFBR-style transient overpower accident would thus be impossible in the molten-salt hybrid. The MSHR is also immune to core-melt-type accidents and fuel rod failures. In addition, a loss-of-coolant accident is essentially impossible in the MSHR; under extreme situations the blanket salt could actually be drained to a storage tank integral to the system. Finally, the blanket salt does not react chemically with air or water.

The MSHR's safety attributes must, of course, be assessed in terms of relative costs and benefits. It should be noted that the results of in-reactor tests conducted in both England and France showed the LMFBR to be intrinsically safe because of the large sodium heat sink's ability to remove after-heat by natural convection if pumps failed. The caveat, therefore, is that the "real" safety margin between the MSHR and LMFBR may not be as large as might first appear.

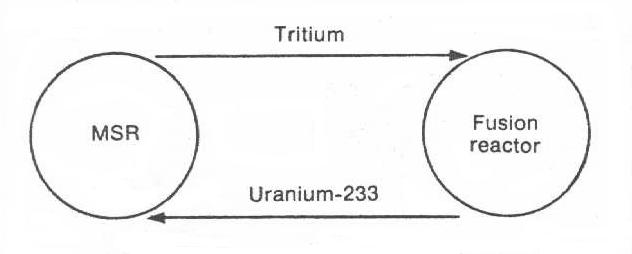

An intriguing approach to fusion-fission systems, based upon initial studies conducted at Oak Ridge National Laboratory, has been suggested by V.L. Blinkin and V.M. Novikov of the I.V. Kurchatov Institute of Atomic Energy.

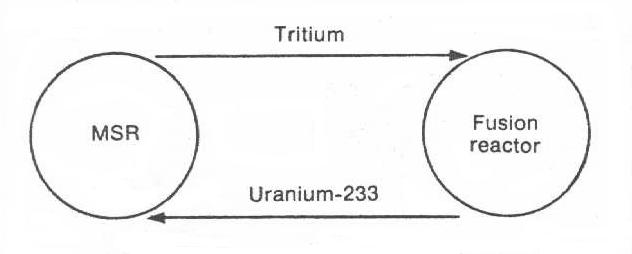

4 Their idea is to introduce fuel factories as small units connected "symbiotically" to molten salt converter reactors (MSRs). The linkage is symbiotic in that the MSR is the source of all tritium used by the hybrid while the hybrid is the source of all U-233 used by the MSR. A glance at Figure 4 and Table 2 shows that the method by which this is achieved involves altering the salt composition of the fuel and blanket, eliminating fertile thorium from the former and lithium from the latter.

|

Figure 4. Symbiotic Molten Salt Hybrid System

Blinkin and Novikov's suggestion is essentially to build a fission reactor with a fusion appendix. The advantage claimed for this "symbiotic" arrangement is that a nonbreeding MSR and a small, low-power tokamak are feasible with current technology. The tritium-getter properties of the MSR's sodium fluoroborate coolant would eliminate the tritium headache that so often besets designers of fusion systems. Blinkin and Novikov claim that there is a further benefit in dividing the processing system between two reactors, because of the complexities involved in removal of both fission-product rare earths and protactinium at the same time. Fission product removal would take place in the MSR, and protactinium and uranium removal would take place in the fusion reactor. |

|

Table 2

Operating Parameters of Molten Salt Symbiotic System

MSR fuel salt composition LiF - BeF2 - 233UF4

(50.0 - 50.0 - <0.1 mole%)

Fusion reactor molten salt NaF - BeF2 - ThF4

blanket composition (71.0 - 2.0 - 27.0 mole%)

Thermal power ratio MSR 11:1

to Fusion Reactor |

Blinkin and Novikov's arguments in favor of the symbiotic arrangement are as follows.

First, given the MSR's proven tritium-handling method and the reduced fuel needs of a small hybrid, the so-called tritium problem in fusion power would be reduced to easily manageable proportions.

Second, the full reprocessing system of the MSBR has never been demonstrated on the scale of an operating commercial reactor. By splitting the tasks (fission product removal and protactinium or uranium isolation) between two reactors, reprocessing is greatly simplified. This would keep capital costs down and shorten the engineering lead time.

Third, breeding systems with short doubling times are needed to sustain a rapid penetration of nuclear power into the energy economy. The MSBR's doubling time of 20 years is far too long. With the LMFBR a potential plutonium bottleneck could occur. Each LMFBR requires approximately 23 LWR-years of operation to provide its fuel inventory; hence, a more than modest growth in demand could find insufficient plutonium to bring needed LMFBR capacity on line. The symbiotic system would have a much smaller fissile inventory than the LMFBR, which with a doubling time of 4 to 5 years could grow at a rate sufficient to keep pace with any foreseeable energy demand.

Fourth, the intrinsic superiority of on-site reprocessing over conventional reprocessing in lowered fuel cycle costs, simplified waste handling, and elevated capacity factors makes fluid fuel systems particularly attractive.

One interesting aspect of Blinkin and Novikov's scheme is that the MSR could be installed as an independent system with linkage to the hybrid to follow later. This means that if, as is likely, the deployment of the hybrid lags behind that of the MSR, MSRs would still be able to contribute to energy needs.

Which of the above systems holds the greatest promise is a matter of conjecture, although there are some persuasive arguments being made in favor of the fuel factory approach. From the economic standpoint, so the main argument runs, the fissile fuel produced in a hybrid is more valuable than the electricity generated. Hence, the support ratio becomes the controlling factor. For a power hybrid to compete, it would need a support ratio roughly equivalent to that of the fuel factory. Another argument is that a fuel factory should be a less complex installation. Fission suppression makes the engineering of the reprocessing system more tractable in a fuel factory, and, of course, there is no need for all the ancillary plant (steam generators, turbines, and so on) that would be a part of any power hybrid. Only time will tell whether these arguments prove to be correct.

It should be remembered that the hybrid is closely linked to a large fission power economy.

5 A commitment to the development of the hybrid is, therefore, ipso facto a strong endorsement of nuclear power. It is also an equally strong endorsement of pure fusion. Edward Teller has likened the direct approach to pure fusion to scaling a mountain in one giant leap, while he views the development of the hybrid as a leisurely walk to the top. Although this probably exaggerates the difficulty of achieving pure fusion, it points up the importance of the pedestrian approach, via the hybrid, as a sure way of getting where we want to go.

Notes

- Roy C. Robertson (ed.), "Conceptual Design Study of a Single Fluid Molten Salt Breeder Reactor." June 1971, ORNL-4541. J.D. Lee, "The Beryllium/Molten Salt Blanket -- A New Blanket Concept." April 25, 1979; prepared for submission to Proceedings of the Third US/USSR Symposium on Fusion-Fission. Princeton, New Jersey, January 22-26, 1979; UCRL-82663.

- Proceedings of the Second Fusion-Fission Energy Systems Review Meeting, Nov. 2 and 3, 1977, Washington, D.C., July 1978, CONF-771155.

- M.M.H. Ragheb, R.T. Santoro, J.M. Barnes, and M.J. Saltmarsh, "Nuclear Performance of Molten Salt Fusion-Fission Symbiotic Systems for Catalyzed D-D and D-T Reactors," March 1979, ORNL/TM-6560.

- V.I. Blinkin and V.M. Novikov, "Optimal Symbiotic Molten Salt Fission-Fusion System," I.V. Kurchatov Institute of Atomic Energy, Moscow 1977, IAE-2819 or UCRL-trans-11288.

- Leonard F.C. Reichle. "Potential for the Molten Salt Breeder Reactor," presented to AIF Conference on U.S. Options for Long Term Energy Supply, Denver, Co., June 20, 1977.

Glossary

Blanket -- generally speaking, a region in either a fusion or fission reactor where fertile material absorbs neutrons in order to breed fuel. In hybrids, blankets can also act as energy multipliers.

Breeding ratio -- ratio of the number of fissile atoms produced to fissile atoms consumed. For the MSBR, a breeding ratio of 1.065 means 106 atoms of fissile fuel produced for every 100 atoms consumed.

Doubling time -- the amount of time required for a breeder to produce enough fuel to start up another reactor of similar capacity.

Thermal reactor -- a fission reactor in which the neutrons are in thermal equilibrium with the core. The average energy of thermal neutrons in such a reactor is 0.025 eV.

In situ reprocessing -- means that reprocessing takes place on site and is integral to the reactor system. Reprocessed high level wastes would be in a form that would permit them to be stored in a special containment cell inside the biological containment of the reactor.